MAS GROUP MAKINE is the partner of machines

With our professional experience, we are sharing our success with our customers

SCREW AIR COMPRESSOR

Screw compressors are a key power source for numerous industrial applications and processes, offering both efficiency and cost-effectiveness. Their operation involves a screw block, where two rotors within a housing engage to compress air.

Air enters through the suction port into the compression chamber, filling the spaces between the rotor teeth. As the rotors turn in opposite directions, they seal the suction opening and create a compression zone between the housing and the rotor teeth. The rotating rotors force the air through the progressively narrowing gaps between the teeth, resulting in compression. The compressed air is then expelled from the outlet of the screw block.

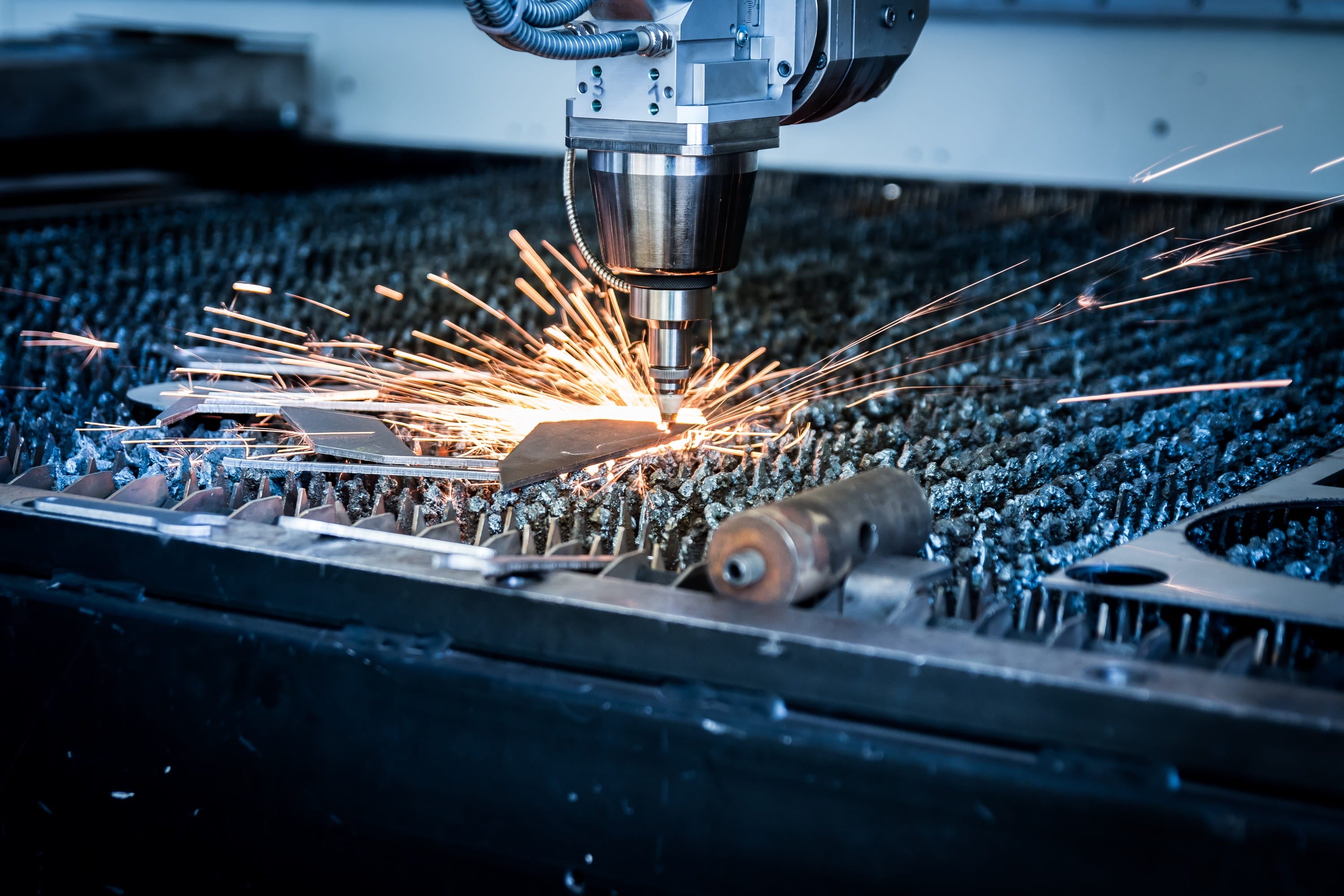

NITROGEN LASER CUTTING

**Why Choose the Nitroplace Laser Cutting System?**

- Generates nitrogen gas more economically with reduced energy consumption.

- Achieves maximum nitrogen purity with minimal energy usage.

- In a 230 Bar system, 1 kW of electricity produces 1 Nm³ of 99.999% pure nitrogen gas.

- Features the lowest air-to-gas ratio.

- Capable of cutting all types of metals.

- Eliminates the need for liquid nitrogen or bulky tanks.

- User-friendly operation.

- Provides industrial solutions customized to your needs.

- Specially designed for optimal performance.

- Includes online connectivity for convenience.

Airplace Laser Cutting Systems

The 18-bar oil-free dry air system is a cutting-edge, high-performance solution designed for metal cutting. It stands out as the most economical and highest-quality oil-free dry air system available, delivering exceptionally clean air for metal cutting applications. Its energy efficiency also makes it environmentally friendly. This system enhances laser cutting precision for stainless steel, galvanized sheet, ERP, DKP, aluminum, and copper, resulting in cleaner, more accurate, and perfect cuts.

Full Automatic Volumetric Vertical Packaging Machine

Products to be packed:

Pulses, Chips, Cereal, Sugar, Salt

General Characteristics:

Volumetric weighing system,

Weight sensitivity depends on the size of the items to be filled,

Filling capacity between 100 and 1000 grams,

PLC controlled, touch screen,

The right and left settings of the packaging are made by a reducer motor,

The product contact surfaces made are from stainless steel: ANSI 304-CR-NI,

Easy forming collar replacing,

Cost effective,

Sophisticated design